Benefits for Safety

Allows For a Safer Work Environment

Warns of Excessive Mill and Saw Vibration

Warns When Saw Has Lost Tension

Warns When Saw Has Extreme Cracks or Bearing Failure

Kickbacks can save the saw during extreme snake or snags.

The Mill Safety lights feature from Saw Control consists of a visual display on the mill floor. In a nut shell the Saw Control will have an alarm set point established for allowable vibration, and anytime the vibration duration limit is exceeded the output circuit will be activated.

Benefits for Mill Management

Aids in Safety by alerting of machine or saw problems

Allows for production to be based on saw blade and machinery capability.

Gives an overall “picture” of how the mill is performing

Aids in reducing fall-down grade

Assist in reducing unscheduled saw changes

Assists in reducing target sizes

Aids in increasing saw blade life

Helps proficiency of mill personal

THRU-CUT gives you full production after lunch, before or after a long weekend, when the operator isn’t having a good day, or any other production time lag.

Benefits for Filers and Maintenance

Alerts guide buildup and/or guide wear problems

Aids in determining saws for correction tension, tire and tooth shape

Alerts of bad saws or guides without culling wood

Warns of bearing problems

Shows saw cracks

Shows dull/sharp saws

Assists in training of new filing personnel

Aids in targeting maintenance of band-mill and carriage

Assists in evaluating saw filing equipment

Gives overall “picture” of alignment in real-time

Assists in sorting out machine alignment and saw-tooth problems

Aids in getting mill maintenance and fliers working together

The greatest benefit seems to be the filing personnel calling for saw changes on their own. Also the ability to know if the “snaking” is due to a weak saw or trash buildup on the guide. These events result in steady production and balance work loads in the filing room.

Benefits for Quality Control

Aids in determining where problems occur – saws or feed-works with the light display visible on the mill floor QC will be alerted when sawing begins to exceed acceptable sizing. This allows QC to focus on size and grade issues from multiple machine centers with confidence that out of spect lumber will not be found down line in the process.

Alerts

Deviation

Do you have an affiliate program?

Benefits for Machine Operators and Sawyers

Alerts when problem log is being cut

Aids in determining if / when saw change is necessary

Allows maximum feed speed on good saws

Warns when there is guide buildup and/or wear

Warns of poor performing saw

Assists in training of new operators

More Real Saw Control “that can’t be beat.”

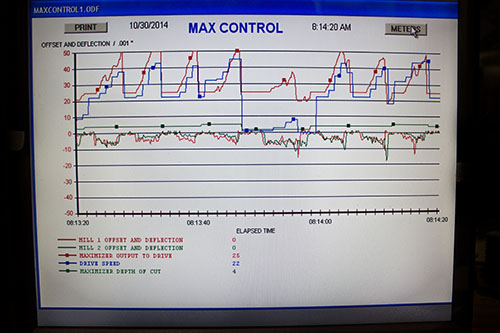

Saw Control’s automatic speed control reduces sawing variation allowing for reduced target size, improves sawing efficiency and providing real time and historical quality analysis. And Saw Control does it all at faster feed speeds.

Minimum Target Size is determined by worst-case scenarios. Standard Deviation needs to be reduced to shrink the bell curve distribution of measured lumber. Many mill QC programs operate on a random basis after the lumber has been manufactured.

Real Time Control with Saw Control III is a better option than addressing quality after lumber is cut. Saw Control monitors & controls saw blade movement at the machine center.

Contact Saw Control

Contact Saw Control today to get started!